Welcome

INTERMOUNTAIN SLURRY SEAL’S MICROSURFACING AND SLURRY SEAL GENERAL INFORMATION

This web page is dedicated as a resource for all stake holders in an effort to provide the following; describe the benefits of micro-surfacing & slurry seal applications, the typical construction processes we follow, help answer questions you may have, and what you as a resident can do to help create a successful project. The information on this page is general and your specific project may have unique differences.

Micro-surfacing and Slurry Seals are cost effective pavement treatments used as preventative maintenance to extend the life of underlying pavements. These applications are designed to prevent water infiltration, sun oxidation, and provide a new wear surface with added skid resistance. A thin layer of asphalt emulsion, crushed aggregate, chemical additive, and water are applied out of a spreader box and allowed to cure. Micro-surfacing was pioneered in Germany in the late 1960s and early 1970s, being first introduced in the United States in 1980. Intermountain Slurry Seal has been performing micro-surfacing and slurry seals since 1985. Micro-surfacing and Slurry Seal treatments are far less expensive than a tradition mill and fill and construction inconvenience to residence and travelers is far less.

FEDERAL AND STATE ENTITIES INTERMOUNTAIN HAS PERFORMED MICRO-SURFACING AND/ OR SLURRY SEAL TREATMENTS FOR:

- Federal Highway Administration

- Arizona Department of Transportation

- California Department of Transportation

- Colorado Department of Transportation

- Fort Hood Airforce Base

- Good Fellow Airforce Base

- Idaho Department of Transportation

- Montana Department of Transportation

- Nevada Department of Transportation

- New Mexico Department of Transportation

- Oklahoma Department of Transportation

- Utah Department of Transportation’

- Texas Department of Transportation

- Washington Department of Transportation

- Wyoming Department of Transportation

CITY AND COUNTY ENTITIES INTERMOUNTAIN HAS PERFORMED MICRO-SURFACING AND/ OR SLURRY SEAL TREATMENTS FOR:

- City of Albuquerque, NM

- City of Ada, OK

- City of Amarillo, TX

- City of Austin, TX

- City of Baytown, TX

- Bexar County, TX

- City of Dallas, TX

- City of Kerrville, TX

- City of Las Cruces, NM

- City of Lubbock, TX

- City of Midland, TX

- City of North Richland Hills, TX

- Provo City, UT

- City of San Antonio, TX

- Salt Lake County, UT

- Spanish Fork, UT

- St. George, UT

- City of Sioux Falls, SD

- City of Weatherford, TX

*The list above is a small sample of agencies who have annual micro-surfacing and slurry seal programs

Best of all, micro-surfacing and slurry seals are ECO-FRIENDLY helping to reduce green house gas emissions. According to an environmental impact study performed by BASF Corporation, micro surfacing is significantly less harmful to the environment as compared to other methods of road reconstruction.

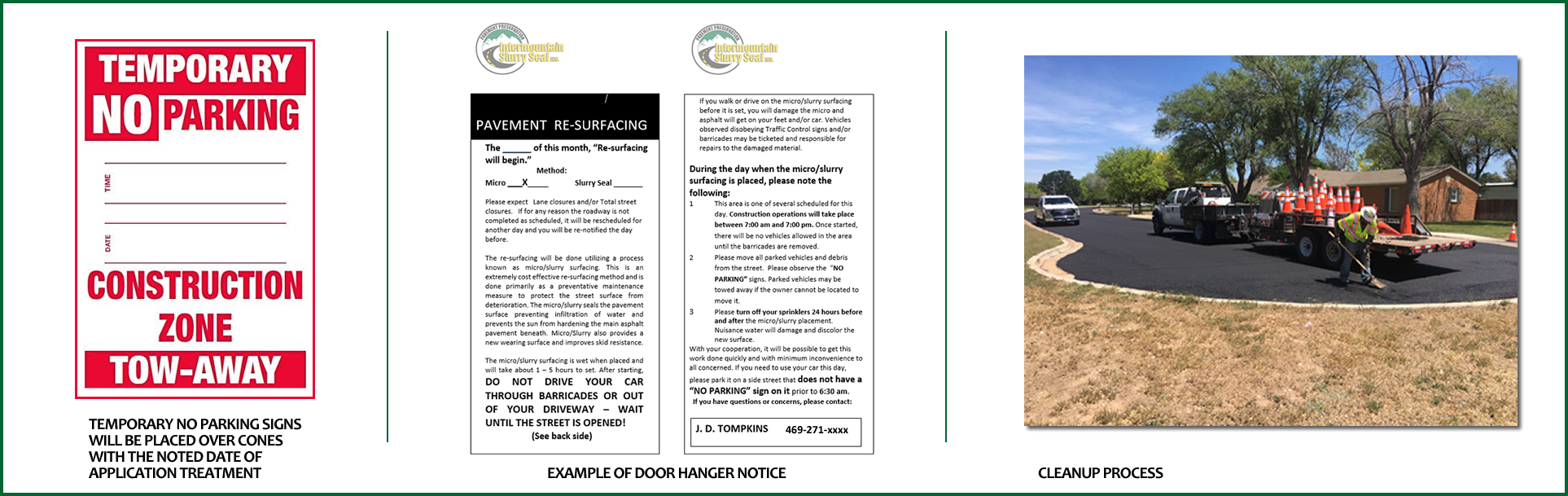

NOTIFICATION PROCESS – Intermountain Slurry Seal will place a door hanger notice on your front doorway a minimum of 24 Hours before the day of construction. The construction notice will inform you what day your street is scheduled to be closed or partially closed. Please do not park on the roadway or we will not be able to complete your street.

CONSTRUCTION PROCESS – Intermountain Slurry Seal will first prep and pre-clean your street. Utility covers such as manholes and water valves will be protected and pavement markings if applicable will be documented. Street sweeping, weed removal, and general clean up of the roadway will take place. When the street is fully prepped the placing crew will arrive and begin the application process. The application time is dependent on the size of the street and how long it takes our material trucks to load and place the material.

CURING PROCESS – The material is placed wet and needs time to cure. The curing process is the water coming out of the mix. The material can stay generally soft depending on the weather and atmospheric temperature for a period of weeks. This is normal and part of the process of the chemistry expelling the water overtime.

OPENING PROCESS – When the material is sufficiently cured workers will remove barricades and road closed signs allowing access to your street. Once traffic has been allowed back on the new surface, vehicles will continue to improve the overall smoothness and texture. Areas such as paving seams and hand work will become smoother and less noticeable.

FAQs

- WHAT CAN I DO TO HELP MAKE THIS PROJECT A SUCCESS?

- Obey the traffic signs and closure. Safety to you and our workers is paramount. Following the traffic signs and instructions will help insure all of our safety.

- On the day your street is scheduled for construction please turn off sprinklers. Park in the driveway or on an adjacent street. Typically streets that are adjacent are not scheduled on the same day in an attempt to allow access to your residency.

- Avoid sharp turning movements in your vehicle. Power steering turns and sharp movements can easily damage the micro-surfacing and slurry seal for the first several days.

- WHEN CAN I DRIVE ON IT?

- When the workers have left your streets and pulled the barricades.

- HOW LONG DOES IT TAKE TO DRY?

- It is dependent on the temperatures and climate. Typically 2-4 hours. The longer the material has to cure, the better the finished product.

- WHY ARE YOU NOT AT MY STREET YET?

- Typically we are scheduling 5-10 streets per day. We are planning to be to your street, but depending on the size it may be scheduled near the end of the day. If unforeseen weather (Rain) occurs you will be re-notified for a later date.

- MY NEIGHBOR DROVE THROUGH THE MATERIAL, WHEN WILL YOU COME FIX IT?

- At the end of the project we will put together a punch list and plan all necessary repairs. Tire tracks and damage to the micro-surfacing/ slurry seal that are not down to the underlying pavement are typically not repaired and in time become less noticeable.

- I HAVE AN APPOINMENT WHAT CAN I DO?

- Please contact the onsite superintendent on the bottom of the notice to schedule any special accommodations. We will not be able to accommodate all requests, but emergency type situations will be worked around.

- I SEE LOOSE AGGREGATE AROUND MY CUL DE SAC OR NEAR MY INTERSECTION, IS THIS NORMAL?

- This process is similar to applying hot mix asphalt, only we are applying it cold. The material needs time to cure and the initial opening of the street to traffic can create minor “raveling”. Raveling is a normal part of the process, and if necessary, a post sweeping operation will occur.. The micro-surfacing/ slurry seal integrity has not been jeopardized.

- I HAVE A DELIVERY SCHEDULED WHAT CAN I DO?

- We would please ask you to reschedule the delivery. Heavy delivery trucks, skid steers, and fork lifts can cause damage to the micro-surfacing and slurry seal until it is fully cured.

- WHY DOES THE TEXTURE IN FRONT OF MY HOUSE LOOK DIFFERENT?

- Some areas and certain circumstances require workers to use hand tools to spread the material. Anytime this happens the overall surface will have a different appearance. We do our best to minimize these instances, but it is typical for both the micro-surfacing and slurry seal processes. The integrity of the material is not in jeopardy and the area should improve over time with traffic.

- WILL MICRO-SURFACING AND SLURRY SEAL CRACK?

- If the underlying pavement has existing cracks micro-surfacing and slurry seal will be susceptible to reflective cracking. The reflective cracking will be smaller, but still need to be crack sealed in the future to prevent water infiltration.